|

Above

two photos show a whole batch of parts that were sent off for zinc plating and

are now back, good as new. The plated parts get one of three different finishes,

known as black, yellow and clear. The zinc plating resists corrosion, in addition

to giving the parts a like-new look.

The

oil tank after masking and painting.

On

the rotisserie, the underside of the RSR continues to receive attention. Here

some previous (and rather crude) modifications to the foot pedal box have been

put right (you're looking at the underside of the cockpit footwell. The pedal

assembly mounts in the square depression you're looking at the underside of, and

the two forward-facing holes are where the master cylinders connect.

Years

of carelessly-placed floor jacks has caused several areas of the car's bottom

to be caved-in, and those areas are all pounded out one at a time, and remaining

imperfections filled.

Some

damaged areas are easier to repair by cutting them away, as this section of the

front crossmember has been, then pounding the metal back into proper shape and

welding the repaired piece back in place (see next).

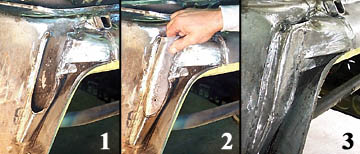

Here

is an example of the technique mentioned above. In this case, part of the lower-rear

of the left door jamb, near the jacking point for the left-rear, was so badly

bashed in it had to be cut out (Pic1) to be repaired. The cut section, seen being

held in place in Pic 2, was pounded back to its correct shape after being cut

off. The repaired part is welded back in place and ground down (Pic3), and will

look good as new after primer and paint.

The

front strut housings being reassembled

The

doors, which we saw being chemically stripped a few days ago, are getting closer

attention, including bead-blasting. As with the chassis we've seen already, imperfections

in the doors will be corrected, filled and primed. <<<

Previous Update | Next Update >>> |