906-138

October 14, 2002

The only thing

this picture shows is the rubber missing from around the windscreen.

The rubber had to be removed by hand (knife, chisel, pick).

Here is a better

shot. The small hole on the right is for the electric cutoff

switch.

Hours

and hours of tedious work to save the original edges of the

window and the body.

There

was a slight crack at the base of the windscreen so we re-glassed

it with epoxy. Epoxy resign is a little more crack resistant

and this is in a vulnerable spot for cracks.

Here is a shot

of the oil filler hole glassed up.

The next step will

be to drill a symmetrical hole so we can line up the oil tank

and cap.

Once this hole

is made we can get a visual of the oil cap and cut a precise

final hole so the cap is centered.

Jack is finalizing

the door seal grooves ( What a job!).

You can see the

amber color is the extension of the old worn out doorsill.

This was added so we can cut a straight line above the side

pod.

The groove is now

ready for a little bodywork.

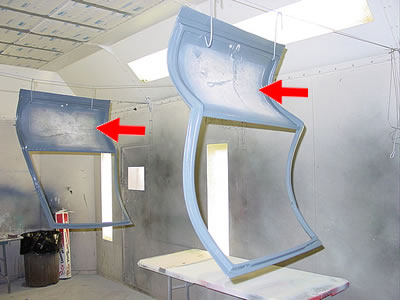

Don't adjust your

computer! The doors are upside down because it's the only

way to prime both sides (Duratec).

When the primer

dries, the light area at the base of the door will be reskined

in "S" weave glass.

The door will be

sanded and painted navy gray on the inside.

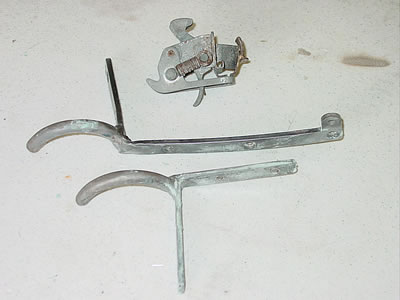

This is

the factory installed hinge so that the door opens forward

and not up (gullwing style). It's a little crude but that's

the way it was done.

These

hinges will be re-plated silver zinc, but we will use them

now for fitting the door.

<<

Previous Update | Next Update >>