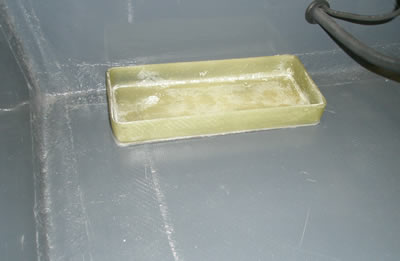

Andy has remade a battery box and is about to glue it in.

|

Epoxy cabosil is used as the glue.

|

A few finger dabs here and there.

|

All glued in. Andy will use some small button-head bolts for a more secure feeling of attachment.

|

This is a non-original strap that we make. Originally they were held in with a rubber band, but that is not legal today for racing purposes.

|

Sent the sidepods out about 4 months ago and they came back 2 weeks ago. Now we have to make all of the fittings to take the fuel from tank to tank and to the engine and filler.

|

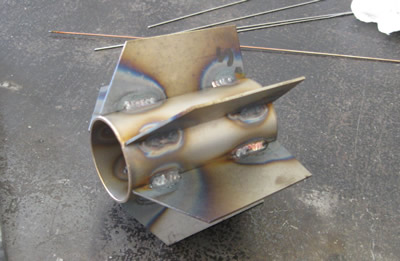

Here are the cookie cutters for the exhaust.

|

We had to make them because they are not available at this time.

|

Bret's making the bracket to hold the pipe to the pipe hanger (which is attached to the transmission).

|

Welded and ready for powder coat.

|

Pretty, eh?

|

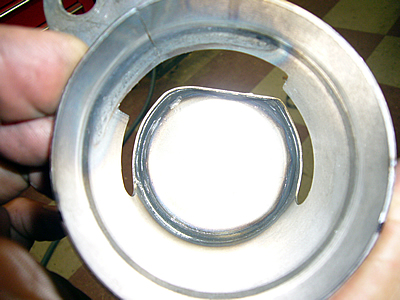

We had to re-core the oil cooler because it had a few leaks in the middle from a lot of years and a lot of use. The end caps are original (just chopped off the original cooler).

|

Early 906's didn't have brake cooling ducts, but everyone added them later.

|

This car was raced extensively so there were some pretty crude ducts and that's why we are making nice ones.

|

These are like 910 style.

|

Looks like something from a jet engine exhaust.

|

This is how we make the parts.

|

We put a piece of metal between 2 homemade dies.

|

And then squeeze the shit out of them!

|

Then we trim the crinkled metal away.

|

The part is put back on the die so Bret can cut the slot for the disc. Notice the hot sauce in the background. No, I don't know why it's there, but it looks hot!

|

Bret's handy work. You get it?! Handy!

|

Weld the bracket on and...

|

...some powder coat (because it's more durable to the heat) and then the part is ready for installation.

|

The front has the air duct attached to the control arm. That's how they did it in the day.

|

Doesn't the suspension look pretty?!

|

This works just fine.

|

We have finished the pressure mold to make these duel duct inlets and Andy is fitting them to the chassis and the tail.

|

This ain't no easy job because no tail and no entrance duct in the tail are the same from car to car. Everything has to be hand fit.

|

Sometimes it takes 6 hands to accomplish this. You can see the 3 cleco clamps holding the duct to the frame pipes. This is how Porsche did it using sheet metal screws for the final attachment.

|

I made the carburetor shields last week.

|

You can see the outlines of the holes I have to drill this weekend when that is finished we will install them.

|

These are the 2 tail support cable strap mounts. Then they get screwed to the inner fender well. The cable that holds the deck lid open, hooks up to them and then the cable is hooked to the islet on the chassis.

|

Andy has installed the tail lights and I'm sure the wire harness is in there too.

|