904-067

July 2, 2003

For weeks we've

been working on rebuilding the suspension components and now

we get dirty with the chassis and the undercarriage.

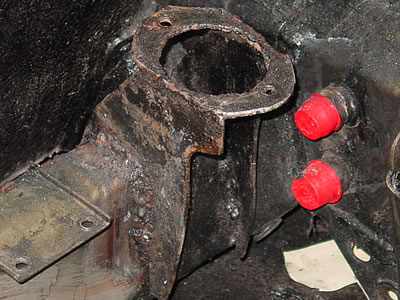

We've decided to

remove these homemade motor mounts and replace them with a

factory 904-6 type center nose mount.

Removing

the paint is a very tedious job. In this area with the oil

pipes, it will definitely be easier to get this corner to

bare metal when the engine mount is removed.

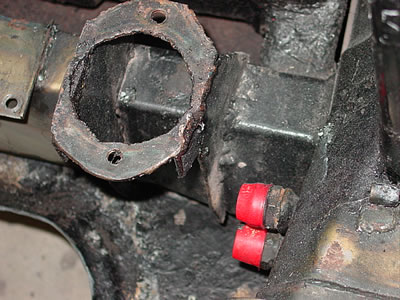

You can see there

was no attention to detail when these mounts were made and

welded in.

This is what we

call "GLOB WELDING"!

This mount is as

bad as the other.

Nice round hole!

This hole is a

little better.

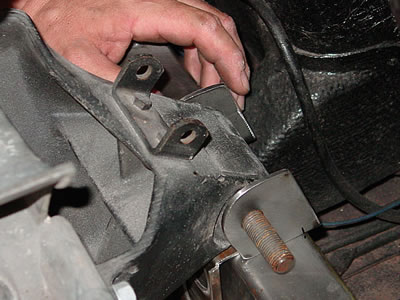

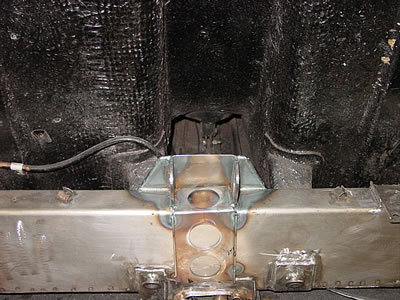

The mount is being

indexed with the engine and transmission, assuring a perfect

fit.

After a week of

grinding on the chassis, Mark steps in for the chassis repair.

This mount is identical

to a 906 Prototype mount.

The parts are fabricated

and then welded to the chassis beam.

Welding away!

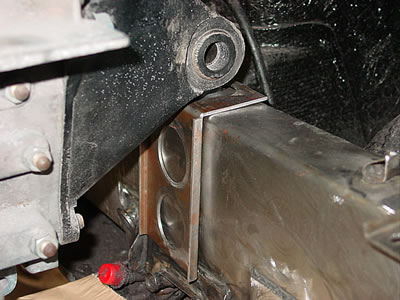

The mount is now

installed and Mark is completing the clearance hole where

the bulkhead was cut for the starter motor.

Mark has ground

the bulkhead to a perfect radius and is now installing a piece

of sheet metal to give the bulkhead strength.

The mount is complete

and you can see where the other two mounts have been removed

and metal finished.

This is

the right rear suspension, which we will blame on Peter Gregg

(the Sebring crash).

Peter

can't defend himself, so it's easy for us to blame him. Note:

the inside has the color of rust, but this is only surface

rust. The metal is in very good shape on the inside. This

is common with 904's because the metal was not painted and

didn't have any zinc protection before the chassis was assembled.

It's always good to open up a 904 to see the condition.

The panel that

was removed has been reshaped to original and will be re-welded

and metal finished.

When this

panel is complete, we'll remove the upper panels and do the

same.

Mark is

just finishing the welding and then we'll begin the top section.

This welded area

would be referred to as a taco bracket because of the radius

shape (it looks like a taco shell).

Mark is cutting

the tail and roll bar mount off the bulkhead to remove the

panel underneath.

The arrows are

pointing to the can opener remains from when the panel on

the other side was removed to straighten out the pickup points.

Should we leave them in or take them out?

This is the removed

part which is in good shape, but a little wrinkled. We could

put a new piece of steel in, but we can flatten this piece

and use it in place of new (original is always better).

This is the backside.

We'll do the same thing here as we have on the other side.

You only cut one side out at a time to keep the strength in

the bulkhead (no twisting allowed).

Another shot of

the serial number.

<<

Previous Update | Next Update >>