906-138

September 2, 2002

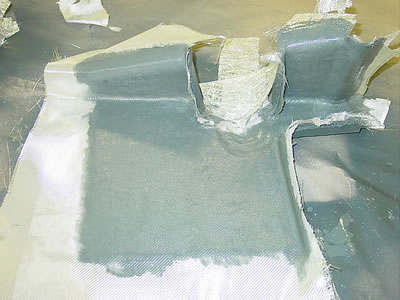

After

a few days at work, gray duratech was painted over the cockpit

surface.

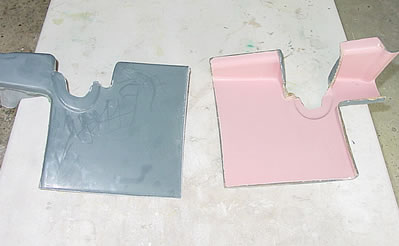

These

are the two front panels, the one on the left surrounds the

dead pedal and the one on the right would be positioned about

the passengers feet.

The inside

of the panels were reskined with a German S-weave. We used

gray pigment which matches the gray paint that will be brushed

on not sprayed.

If you

look closely you can see the edges were sanded with 36 grit

sand paper for better adhesion when the door seal is glued

to all of the surrounding areas. We will use approximately

60mm wide 1-1/2 oz fiberglass mat to make all of the panel

connections.

The dead

pedal panel, which you could see in one of the above pictures,

is actually made in reverse to the other cockpit panels. This

means all of the panels inside the car, with the exception

of the two front kick panels and the floor, are smooth on

the inside. If you notice in the picture, the back smooth

piece is the door seal and the front panel which will be glued

with a mat patch has the cloth surface on the side you are

looking at.

Note, the same

panel is now smooth and the door seal panel to the right has

the cloth surface.

Some pieces are

easier remade than repaired.

We

have molds for most of the Porsche prototypes and now and

again we get to use them.

Luckily, these

two front kick panel molds (which are seen just painted with

gray duratech) are owned by a friend, John Corson, who is

quite a good race mechanic and Porsche restorer. Thanks again

John.

We

wouldn't have to paint the Porsche factory gray (rustoleum

navy gray) because of the gray pigmented panels, but Porsche

painted the cockpit and glass panels gray before customers

received them.

Notice,

I am not wearing respirator because this is a down draft spray

booth, thus making the nasty fumes go through the grates in

the floor long before I breath them. Also, it is about 9,000

degrees inside here Labor Day morning at about 9:15 Florida

time, and if I were to put a mask on sweat would pour off

of my face onto these parts. I guess someone in a hundred

years might be able to prove Kevin built this part through

his sweat DNA.

The part is now

finished and will be trimmed before it is removed from the

mold.

The

curing or drying of the part can be adjusted by the amount

of hardener (M.E.K). In this case, I wanted the parts to install

later in the afternoon, so I kicked it pretty fast. On parts

that have no great structural need speeding up the cure does

not effect the brittleness of the glass. If this were something

like a fender or a wing the cure would take approximately

6 hours to touch and 10 hours minimum before removing from

the mold. This is the process that we use in the summer in

Florida other climates would be different.

The part was removed

at 4:00 and I will install it after Kristie, Sharon (she is

about to become the new reluctant webmaster because Kristie

is going back to school), and myself the web "talker"

are finished with this update.

Here are the two

pieces and the molds side by side. Just for reference it took

me about 5 hours to make the parts and install them, if I

had to save the old parts it would take about 10-15 hours.

<<

Previous Update | Next Update >>