Crash

Repair 904-006

04/12/02

Jack is

putting the finishing touches before we primer paint these

rear deck lid cooling ducts.

Making

a foam plug which represents the inside right support panel

between the fender and the inner "A" piller.

Now mat

and glass have been applied and we will bead blast the foam

away on the back side and install the part.

The part

is now installed in the corner.

Kevin

and Jack are making the inner trunk bottom from the mold that

we made a few days ago.

Jack is

holding the part which we popped out of the mold today. Again,

there were no good molds available for this part so we made

one.

The first

step of making a mold is waxing the surface, as Jack is doing

from the original tail.

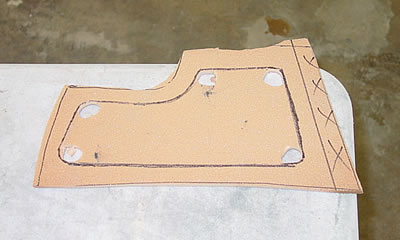

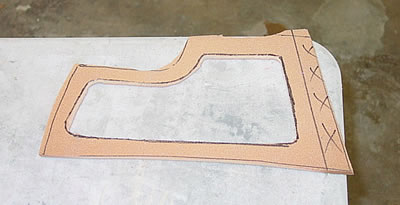

Here Jack

is fitting the fiberglass so that the mold can be laid.

The resin

is getting thicker and Jack's hair is getting thinner (Jack's

46 years old and Ryan below is ..........)

Ryan

is twenty something and he says better no hair than gray hair.

You now

know what the rack was for in the previous pictures. It speeds

the process up more than even we can imagine while working

on the car (lots of glue joints).

The car

is upside down and before we replace the front half of the

floor, which was wiped out in the crash, we will do all the

detail work under the dash. This is a lot easier now than

it would be right side up, working upside down (a drippy mess).

The windshield

wiper motor has to be perfectly placed so that the linkage

does not touch any of the existing fire wall and dash board

panels.

<<<

Previous Update | Next Update >>>